|

||

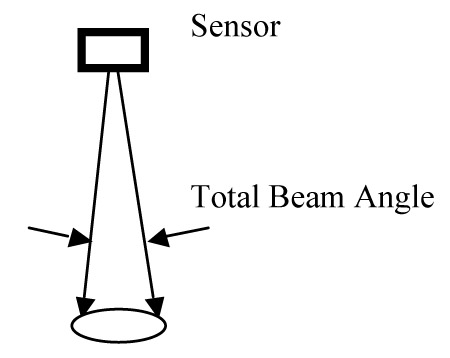

E-Zine January 2012Laser, ultrasonic and radar level measurement sensors direct an energy beam towards the surface to be measured within a total beam angle determined by energy intensity. As the energy beam moves away from the sensor, the beam progressively increases its diameter while containing progressively less energy per unit area. The beam angle is determined by the boundary formed where its energy level is reduced by 50 percent (3 dB). Sensors with smaller beam angles generally emit more concentrated beams (as a percentage of total beam energy) that can generally produce a better and more reliable level measurement. The total beam angle is the illustrated in the figure below. Some suppliers specify the one-half of the total beam angle (that is the angle from the centerline of the beam). Other suppliers state the beam angle without explaining whether it is the total beam angle or the angle measured from the centerline.

The strongest reflections will generally occur due to objects or material within the cone formed by the total beam angle. To avoid additional (erroneous) reflections, the sensor should be located such that there are no obstructions within or near the cone. When this is not possible, a level transmitter that contains features that ignores these additional reflections should be considered. In general, larger ultrasonic and radar level sensors produce stronger beams that tend to measure longer distances with narrower beam angles than smaller sensors. In addition, increasing the sensor excitation frequency tends to make the beam angle smaller and allow measurement of shorter distances in addition to increasing resolution. At least one transmitter is self-adjusting in the sense that it automatically adjusts itself to modify the beam power, pulse duration, beam width and sensitivity in order to improve reliability and performance at different operating conditions and material levels. Excerpted from The Consumer Guide to Non-Contact Level Gauges ISSN 1538-5280 |

||